Vortron Industrial - specializing in the design and manufacture of ultra-efficient centrifugal blowers and air knife systems for industrial drying and cleaning.

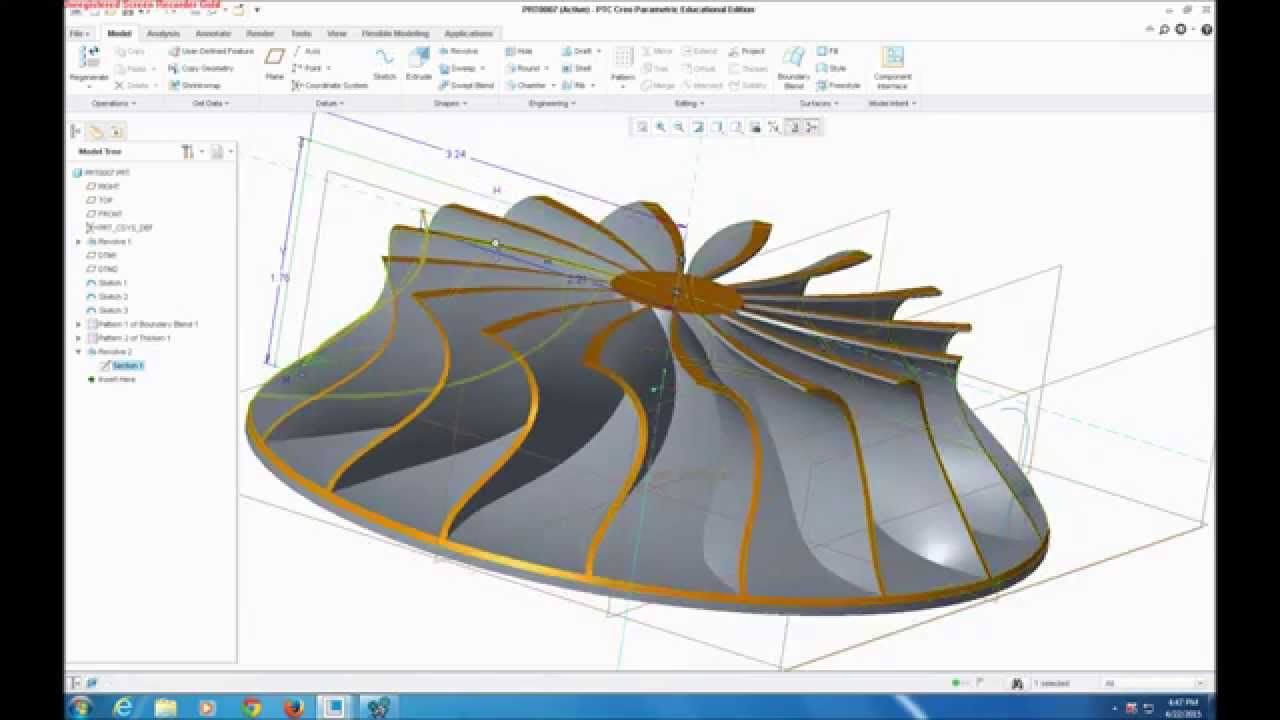

• 92 Downloads Abstract Centrifugal blowers are widely used turbomachines equipment in all kinds of modern and domestic life. Manufacturing of blowers seldom follow an optimum design solution for individual blower.

Although centrifugal blowers are developed as highly efficient machines, design is still based on various empirical and semi empirical rules proposed by fan designers. There are different methodologies used to design the impeller and other components of blowers.

The objective of present study is to study explicit design methodologies and tracing unified design to get better design point performance. This unified design methodology is based more on fundamental concepts and minimum assumptions. Parametric study is also carried out for the effect of design parameters on pressure ratio and their interdependency in the design. The code is developed based on a unified design using C programming. Numerical analysis is carried out to check the flow parameters inside the blower. Two blowers, one based on the present design and other on industrial design, are developed with a standard OEM blower manufacturing unit. A comparison of both designs is done based on experimental performance analysis as per IS standard.

The results suggest better efficiency and more flow rate for the same pressure head in case of the present design compared with industrial one. Fsx - Perfect Flight - Ultimate Crj-700.